The Glass Factory

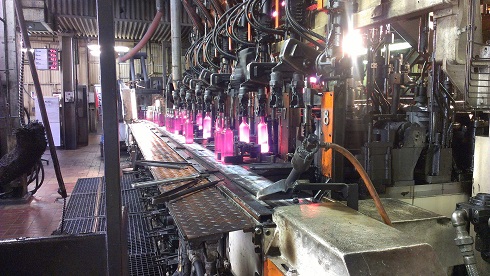

This week, one of my classes paid a visit to the nearby glass bottle company. I also like making picture posts when I’m tired and exhausted from doing real work. Here, the molten glass in dropped into moulds and formed into the proper shape. Many processing lines run parallel, forming various different shapes with different colored glass. If I understood correctly the French, they make 1 million bottles a day and the furnace hasn’t been turned off in 12 years.

A first optical check:

Now, the glass bottles are polished so that they have a nice finish:

More quality checks are done on each bottle to make sure that they are in specification.

A common problem that they face is ceramics getting mixed into their recycled raw material (glass). The reason is that ceramics have a higher melting temperature than glass, so it can clog the furnaces. Additionally, the ceramics also cause the final products to be extremely brittle. So think twice before you recycle that shattered plate! Put it in the trash.

Originally posted on halfwayaroundtheworld.studentsgoneglobal.com.